等离子体气化炉耐火衬 The plasma gasifier furnace refractory layer

等离子体气化炉操作温度高,废物能迅速干燥、热解、裂解,再经过二次燃烧达到无害化,无机物在高温作用下熔融成尾渣,高危废物经过处理能够实现无害化。

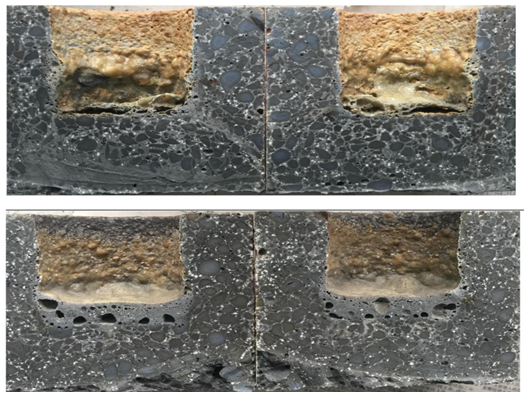

然而等离子体气化炉工作温度高,服役条件恶劣,对炉衬耐火材料提出了严格的要求。目前等离子体气化炉衬主要包括含铬和SiC质耐火材料。含铬材料由于其优异的抗渣性能被广泛用于等离子体气化炉。等离子体气化炉炬口附近瞬间产生高温,会造成严重的热应力损毁,如上海某厂以w(Cr2O3)=41.65%的Al2O3-Cr2O3砖作为等离子体气化炉衬材料,使用20多天后就产生严重损毁。有研究报道,w(Cr2O3)=20%的MgAl2O4-Cr2O3材料与w(Cr2O3)=50%的Al2O3-Cr2O3砖的抗渣侵蚀性接近,且抗热震性更加优良,有利于降低Cr2O3含量;SiC质耐火材料也因具有优异的抗渣性能与力学性能亦被广泛用于等离子体气化炉,同时sic在高温下与X,Y,Z元素反应,造成耐材内衬迅速融毁。

The plasma gasifier has a high operating temperature, the waste can be quickly dry, pyrolysed, cracked, and then harmless after secondary combustion, the inorganic substances are melted into tail slag under the action of high temperature, and the high-risk waste can be realized harmless after treatment.

However, the plasma gasifier has high working temperature and poor service conditions, with strict requirements for furnace lining refractory.At present, the plasma gasifier lining mainly includes chrome-containing and SiC qualitative refractory materials.Chromium-containing materials are widely used in plasma gasifiers due to their excellent slag resistance properties.High temperature occurs instantly near the plasma gasifier torch port, which will cause serious thermal stress damage. For example, a factory in Shanghai with w (Cr2O3)=41.65% Al2O3-Cr2O3 brick is used as a plasma gasifier lining material, and serious damage will occur after more than 20 days of use.It has been reported that 20% of w (Cr2O3)=is close to 50% of w (Cr2O3)=, and thermal shock resistance is conducive to reducing Cr2O3 content; SiC qualitative refractory materials are also widely used in plasma gasifier for excellent slag resistance and mechanical properties, and sic reacts with X,Y,Z elements at high temperature, causing rapid melting of material resistance lining.